Your basket is currently empty!

Share

4 November, 2025

“We previously used plywood on projects like this, but switching to ImpactBoard has made a huge difference. It is easier to handle, performs brilliantly under heavy equipment and keeps the floors in great condition. The site team is very impressed with how well it has stood up to the traffic. We will definitely continue using it going forward.”

– Site Manager, Sisk

PROJECT: Pharmaceutical Facility

CONSTRUCTION MANAGER: Sisk

BACKGROUND TO THE PROJECT

A leading pharmaceutical company is investing €330 million in a new state-of-the-art fill-finish production facility. Sisk has been appointed as Construction Manager for the project, which will create around 600 construction jobs. Phase One is scheduled to be operational by Q3 2027.

The facility requires exceptionally high standards throughout construction. Errigal Contracts is responsible for the delivery of internal floor packages, with consistent protection needed to safeguard completed surfaces from the outset of works.

THE CHALLENGE

The site has experienced intensive construction traffic including:

Standard plywood or hardwood protection traditionally used were reviewed for suitability. However, due to the scale and complexity of the project, there were concerns about durability, handling and the resource implications of replacing damaged materials.

A higher-performance temporary protection solution was required. It needed to maintain floor integrity, support efficient progress and align with sustainability goals.

PROJECT SOLUTION

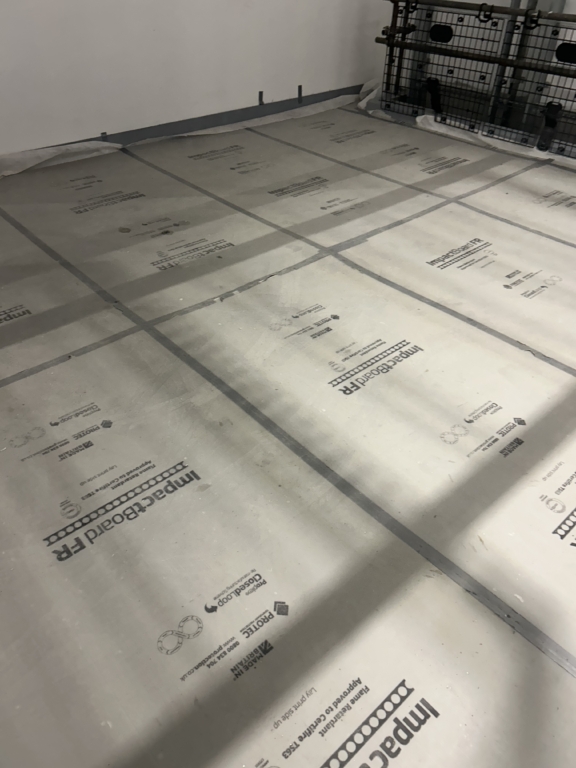

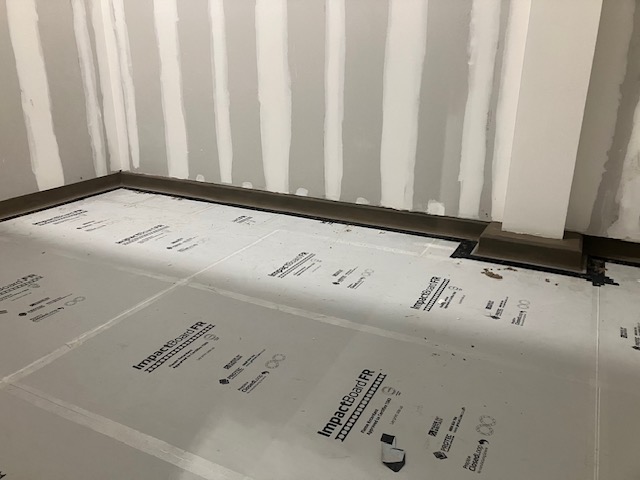

ImpactBoardFR was selected as the primary temporary floor protection.

Engineered for high-load environments, ImpactBoardFR provides:

All materials are fully recyclable via Protec’s ClosedLoop Remanufacturing Scheme, ensuring waste from site is dramatically reduced and contributing to lower-carbon construction practices.

THE OUTCOME

ImpactBoardFR has maintained full structural integrity under the continuous use of MEWPs, scissor lifts and pallet trucks, while also supporting a clean, safe and efficient working environment throughout the programme.

It has reduced downtime typically associated with repairing or replacing damaged protection materials, and through Protec’s ClosedLoop Remanufacturing Scheme has delivered meaningful sustainability benefits by preventing waste and lowering the project’s environmental impact.